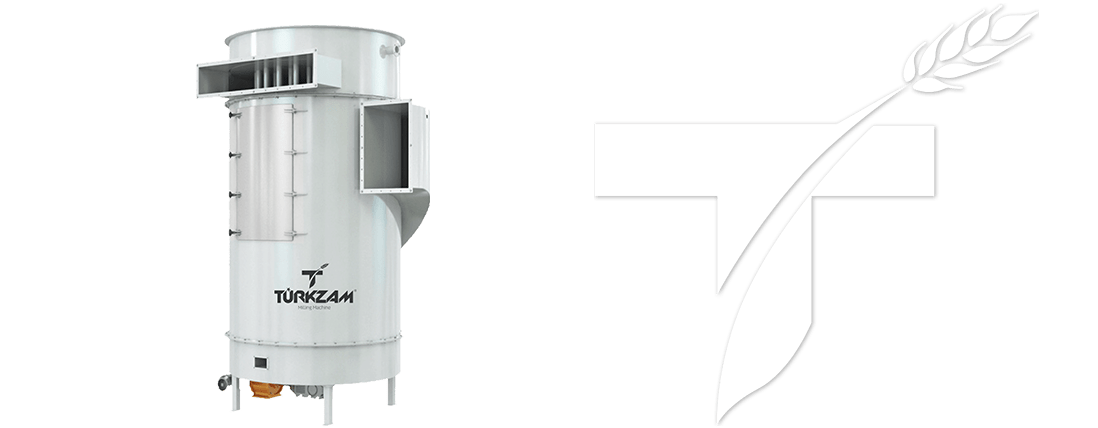

SCOPE OF USE

Suitable to separate dust and other particles

suspended in air of cleaning department aspirator

system before being discharged

to the outside with a bottom scrape.

APPLICATION FIELDS

At food industry

- Flour and semolina mills

- Feed mills

- Dry fruit plants

And other similar food industries

At chemical industry

- Paint factories

- Plastic factories

- Detergent made plants

At wooden industry

At non-ferrous product industry

FEATURES & ADVANTAGES

The filter can be used in the pressurized and vacuum systems. The cleaning of

hose type filter bags is carried out by air at 0.5 bars, which is free of oil and

water

The consumption of the cleaning air is found by this formula: 30 – 40 NLt

(Newton liter) x bag x blow

The optimal flow geometry of the cleaning air route shows as mentioned below:

- The loading capacity of filter for each product

- The max cleaning capacity for each filter bag

- The highest cleaning ratio of cleaned air

- The filter body is combined with cleaning air tank

Therefore, there is no need for an additional air tank

The important criterions of filter loads

In addition to the given effective values at the following, the loading of filter depends on

some other factors such as, chemical reactions, drying, filtration process,

etc. As an example, at wheat cleaning process, in a filter with a 2.4-meter long

bag, maximum loading for aspirator would be 9 cubic meters per minute per

square meter.

TECHNICAL SPECS